Russell Engine Generator Video Presentation

|

This video is a fifteen minute detailed presentation of the Russell Engine Generator. Please click on the image to establish the link. After it appears click again to start the video which can be viewed full screen and in high definition if sufficient bandwidth is available. |

Russell Engine Generator 2 Minute Presentation

|

The Russell Engine Generator 2 minute presentation briefly describes the major attributes of the the only patented, shaftless engine and generator combination in existence. |

Overview of Views A through H

Views A thru H are furnished as an aid in answering engineering questions regarding the design. There is no sound associated with these Videos.

Please click on the image located in each section to establish the link. After it appears click again to start the video which can be viewed full screen and in high definition if sufficient bandwidth is available.

All playing times for Views A through H are approximately 1 minute.

View A - Eng/Gen With Top Case Removed

|

View A shows an operating assembly of the Eng/Gen with the Top Case removed. The Upper Cam Plate (Light Gray) and the Ring Gear (Dark Gray) can be seen rotating around the stationary Block (Blue) and inside of the stationary Generator Coil (Flat Black). |

View B - Upper Cam Plate and Portion of Coil Removed

|

View B is similar to View A, except the Upper Cam Plate has been removed while its associated Cam Track remains and is shown in Red. The Upper Radial Ball Bearing Set, the Cylinders, Sleeves (yellow) and the Cam Follower Bearings (Dark Gray) can be seen within the stationary Block (Blue). The stationary Coil (Flat Black) has been cut in half exposing the rotating Magnets (Gold), Clamps (Medium Gray) and the Armature Ring (Light Gray) of the Cam Track Armature Assembly. |

View C - View B Seen From Above

|

View C is similar to View B, except that the view originates from a point directly above the Eng/Gen. |

View D - Top Sectional View Exposing Pistons

|

View D is similar to View C, except that the entire Block, the Cylinders, and the Sleeves have been cut along their horizontal center line exposing the workings of the Pistons (Green) and their interaction with the Cam Bearings. The Pistons and the Cam Bearing are shown in their entirety. The Fuel Injectors (Black) and the Spark Plugs (White) can also be seen as well as the combustions within the Cylinders. |

View E - Angular Sectional View Exposing Pistons

|

View E shows the Eng/Gen with the Top Case and the Upper Cam Plate removed. The Block, the Cylinders and the Sleeves have been cut in half along their vertical center line exposing the entire view of the Pistons and the Cam Bearings as they interact with the Cam Track in the Lower Cam Plate. The Connecting Pins that attach the Pistons to the Sleeves can be seen, as well as the Exhaust Valve Assemblies mounted in the Block. |

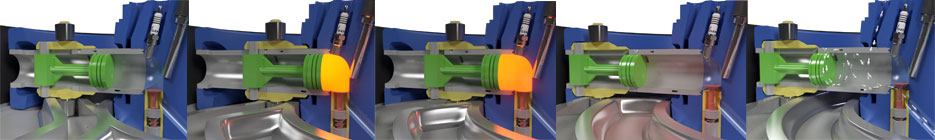

View F - Combustion Process

|

View F is a close-up view of the left side of the Eng/Gen as seen in View E. When the Piston is at the top of its stroke, fuel is injected, the Spark Plug ignites the fuel and the Piston is forced outward driving the Cam Track Armature Assembly. Near the bottom of the Piston stroke, the Exhaust Valve opens decompressing the Cylinder, Purge/Cooling Air cleans and cools the Cylinders, the Exhaust Valve closes, the Cylinder pre-compresses, the Piston moves inward to the top. The cycles repeat. |

View G - Cam Track Armature Assembly

|

View G is an exploding view of the only rotating feature of the Eng/Gen, the Cam Track Armature Assembly. All of the related parts of the assembly are visible in the exploded view. |

View H - Generator Coil Cooling

|

View H is a full side assembly view of the Eng/Gen. Windows have been provided in the case to expose the cooling features provided for the stationary Generator Coil. In this view coolant can be seen as it circulates in opposite directions around the Coil, while absorbing heat from the Coil. The coolant travels through individual ports provided in each case half. |

Video Credits

Anthony Dudek 3D Modeling A. F. Dudek & Associates, Inc. Jennifer O'Connor 3D Animation Ryan O'Connor 4D Artists Inc. Robert C. Russell Sound Dynamic Audio Solutions LLC Laura L. Ripes Voice

If you want to save the video on your computer right click on one of the links below in the format desired and save the video file.

Download 15 Minute Video in WMV format Windows Media Player(100mb file) Download 15 Minute Video in MP4 format QuickTime Player(120mb file) Download 15 Minute Video in FLV format Adobe Flash Video(37mb file) Download 15 Minute Video in 3GP format for Phones and Mobile Devices(7mb file)

Russell Energy Corporation Mission Statement

The Russell Energy Corporation strives to provide the benefits and security of electrical power to all people in the most dependable, affordable and environmentally considerate manner possible.

We are dedicated to the advancement of American job growth, a growing American economy, product quality, and an earned reputation for business integrity.

Consumer Advantages

- Inexpensive to purchase

- Inexpensive to operate

- Inexpensive to maintain

- Plug-and-Play replaceability

- Reduced fuel costs

- Reduced emissions

- Vibration free operation

- Increased dependability

- Increased durability

- Increased service life

- Multi function security (i.e. The Eng/Gen used in a vehicle application can provide emergency electrical power for home use, or for sale to the grid.)

Manufacturing Advantages

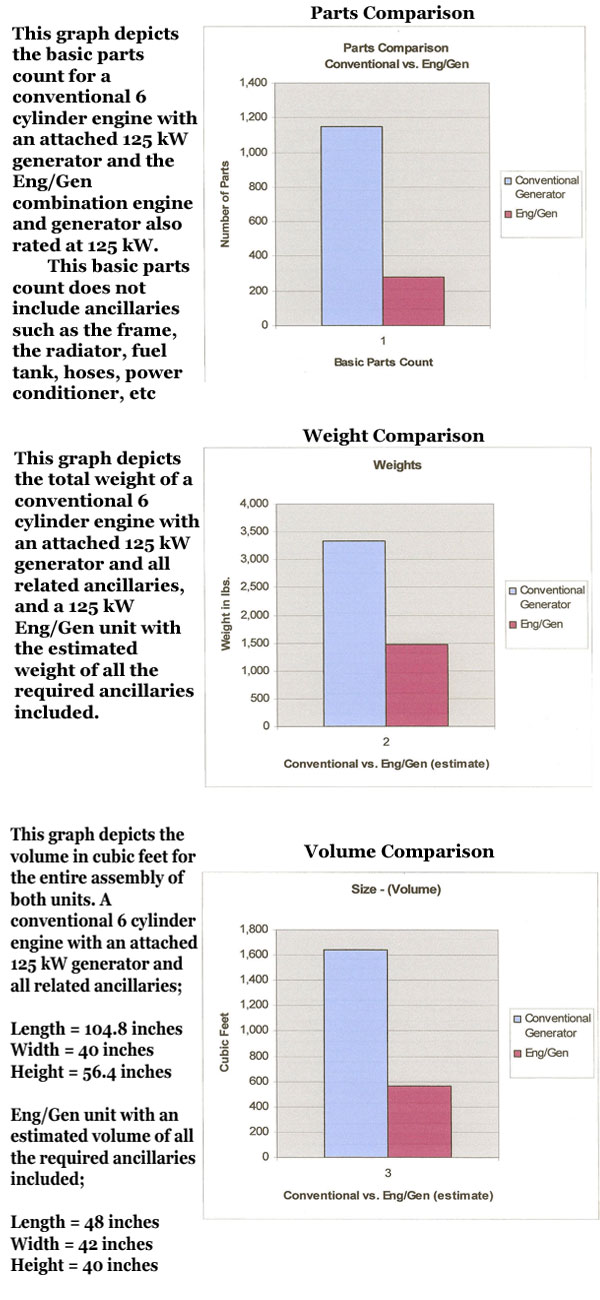

- Low parts count

- No undeveloped technologies required

- No dynamic seals (except for piston rings)

- Most parts are cast with minimal finishing

- No exotic materials

- No exotic procedures

- No unusually close tolerances

- No unrealistic assembly procedures

Design Advantages

- Low parts count

- Vibration free operation

- No undeveloped technologies required

- No dynamic seals (except for piston rings)

- Most parts are cast with minimal finishing

- 4 x the number of combustions (or more), per cylinder during a single revolution (greater power density than conventional 4 cycle engines)

- Direct conversion of rotational energy into electrical energy

- No torque transferred outside the Eng/Gen case

- Sealed construction (waterproof & dustproof)

- Reduced internal energy losses, due to:

- elimination of vibration

- optimized piston movement

- free escape of exhaust gasses

- low pressure purge and intake cycle

- direct conversion to electrical energy

- Reduced internal friction losses, due to:

- two cycle piston movement

- low number of moving parts

- low RPM operation

- low friction bearings

- elimination of mechanical final drive

Environmental Advantages

- Increased energy output (per unit of fuel)

- Reduced fuel usage (based on output)

- Reduced carbon dioxide emissions

- Reduced nitrogen oxide emissions

- Reduced heat emissions

- Wasted fuel consumption is eliminated (in vehicular use with Series Hybrid Drive System)

- Ideal for future (zero pollution) hydrogen fueled applications

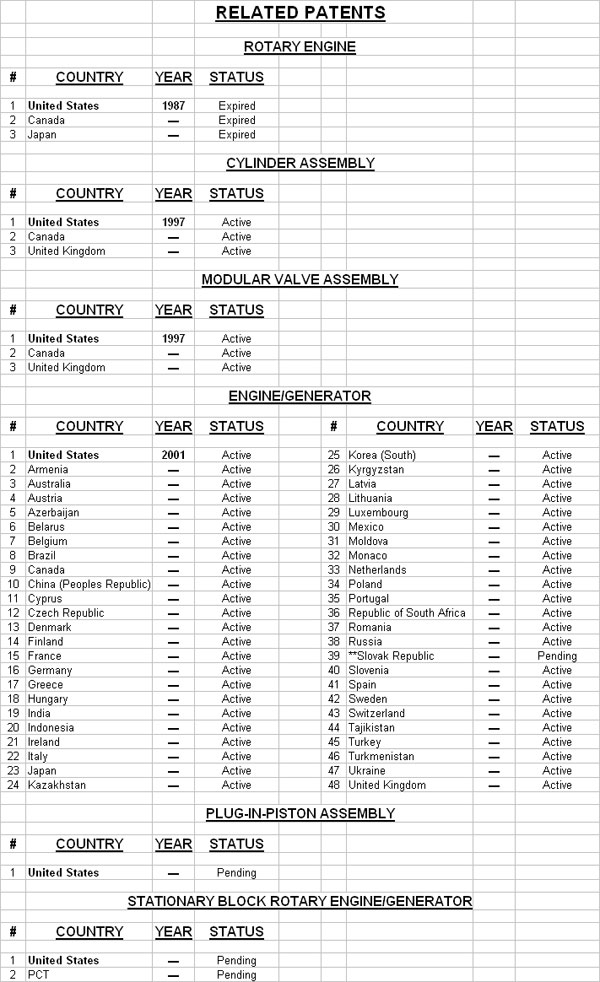

Robert L. Russell President, Russell Energy Corporation (REC)

Inventor of the :

- Russell Rotary Engine (U.S. # 4,653,483)

- Russell Cylinder Assembly (U.S. # 5,636,599)

- Russell Modular Valve Assembly (U.S. # 5,701,930)

- Russell Engine/Generator (U.S. # 6,230,670)

- Russell Plug-In-Piston Assembly (Pending)

- Russell Stationary Block Rotary Engine/Generator (Pending)

The above patents and pending patents are all relative to the current Engine/Generator technology and solely owned by REC along with all related foreign patents. Russell designed, built and tested the original Rotary Engine which formed the groundwork for the development of the revolutionary Engine/Generator. In the course of the development of the Engine/Generator technology, he commissioned and participated in the following related reports.

- Assessment of the Russell Rotary Engine, Southwest Research Institute (SwRI)

- Design Study for the Russell Rotary Engine, SwRI

- Technical Report-Russell Rotary Engine, Ricardo Inc.

Bob Russell is a Journeyman Tool & Die Maker, a co-founder and Vice-President of Power Brake Dies Inc. (retired) established in 1973. This company is a leading and highly innovative press brake tooling design and manufacturing facility in the U.S. and has developed, produced and marketed specialized sheet metal and plate forming tools for industry throughout the U.S. His responsibilities included plant layout, machine procurement, the design of specialty tooling, the machinery and the cutting tools necessary for production, and he was also responsible for the overall manufacturing process. He has designed and built specialty machinery, fixtures and the systems necessary for full-scale commercial production. Several of his proprietary product designs for Power Brake Dies Inc. have been patented and successfully manufactured and marketed.

Charles D. Padgurskis Vice President, Russell Energy Corporation (REC)

He was the former Director of the Information Services Division for the Chicago Police Department (Retired). Over twenty-five years of singular experience in Information Technology and investigative analysis both as a manager and practitioner. Received national recognition for the innovative conception and design of police information tools, development strategies and Police/IT management. Directly led and managed the Chicago Police Department's IT infrastructure and software development with a staff of 150 diverse employees, vendors and contractors servicing a client base of 36,000 internal and external police personnel with an annual budget of 14 million dollars

- As a Chief Programmer Analyst he envisioned and developed the first police data warehouse and the Chicago Police Department intranet to provide a platform for web based queries.

- While serving as the Data Warehouse Manager the data warehouse led to the initiation of the CLEAR (Citizens Law Enforcement Analysis and Reporting) project for the City of Chicago and adopted by the State of Illinois as ICLEAR. The project developed a series of enterprise transaction systems collecting all pertinent police data for inclusion in the data warehouse providing information to all levels for tactical, managerial, analytical, auditing and reporting functions.

- As the Director of Development he led a team of programmers and vendors in designing transaction systems that would provide information for the data warehouse while developing security and audit policies for the enterprise system.

- During his term as the Director of Information Services he instituted best practice policies to reduce down time, reduce expenditures and resolve issues affecting operations including introducing CMMI before his retirement. In addition to managing operations, he also acted as a PMO (Project Management Office) overseeing several Project Managers and their project portfolios.

He was the recipient of several awards from the City of Chicago for his management and development efforts. The Chicago Police Department received the CIO Value Award for 2004 as a direct result of the development efforts of the Information Services Division. The principles and lessons developed during implementation of the CLEAR project were outlined in the U.S. Department of Justice document "Policing Smarter Through IT: Lessons in Enterprise Implementation". He has been a member of the Project Management Institute since 2003.

Joseph A. Scroppo Vice President, Russell Energy Corporation (REC)

Summary: 30+ years experience

- Project/program management (cost plus and fixed price)

- Strategic alliances and project formation/funding

- Proposals, business development, new markets

- Contract pricing, negotiation and management

- Business start-up, new product commercialization

- Turnarounds, new markets, profit improvement

- Government programs: DOE, DoD, EPA, State of IL and CA

Obtained 1 million person hour program management contract with DOE. Garnered $100+ million of Government funding for fuel cell development stage company. Managed world's largest ($35 million) molten carbonate fuel cell cogeneration project. Obtained $2.5 million of DCCA funding from State of Illinois. Managed research, development, demonstration and technology verification programs. Projects have ranged from feasibility studies and market assessments to turnkey $100+ million. Developed new technology business plans and packaged them for investors. Involved in all aspects of commercializing new products including identification of market need, product performance criteria, product costing, manufacturing, laboratory and field testing and line sales. Formed joint ventures and strategic alliances to open new markets.

Industries Served

- Government - fuel cells, environmental, energy, research, development

- Engineering & Construction - refining, petrochemical, chemical, synfuels

- Power Generation - fuel cells, solid waste incineration, cogeneration

- Environmental - projects, products, services, consulting

- Biotechnology - food service, agriculture, wastewater treatment

- Performance chemicals - plastics, coatings, cosmetics/toiletries, food

Work History As president of Bladon International, Inc., assists clients in obtaining government grants, manages projects and assists with commercialization of technology projects based on chemistry, math, physics, biology, environmental technology and engineering. Services include proposal preparation, project definition plans, project funding, project management and business and commercialization plans.

Battelle, Project Manager 2001 - 2006 Under the technology research, education and commercialization center ONR contract, responsible for the development of client business needs, including needs assessment, proposal preparation assistance, commercialization and client market strategy. Assisted clients in obtaining funding for innovative technologies from Federal and private sector sources. Activities included technical, market and business assessments and formulation of product development plans.

M-C Power Corporation, Dir. Business Development, Sr. Project Manager 1988-2000 For fuel cell development stage company, wrote plan/proposal that transitioned technology from laboratory to commercial demonstration. Won 80% of proposals; raised $100+ million development funding. Project manager of world’s largest ($35) million) fuel cell cogeneration demonstration project that met its financial, technical and schedule goals. Managed proposals, developmental programs, project budgets and schedules. Wrote final reports and presented results to sponsors and industry. Prepared business plans and presented investment opportunity documents to raise operating capital. Designed, wrote and produced capability brochures, technical data sheets, advertising and press releases.

InterBio Inc., General Manager 1986-1988 Had profit and loss responsibility for this biotechnology start-up company. Introduced new products to food service, wastewater treatment and agriculture markets. Developed test programs, marketing strategies, new package design, telemarketing and direct mail programs. Set up pricing, distribution policies and obtained new distributors. Established product in McDonald’s distribution system. Proved efficacy of products in field trials. Developed sales collateral, advertising, public relations and sales training programs.

Furmanite, General Manager 1985-1986 Profit and loss responsibility for three profit centers involving high technology on-line machining, valve repair and leak sealing services for power generation and process industries. Turned around Canadian operations within six months. Established budgets, pricing strategies, negotiated contracts. Managed field service teams and emergency response programs. Developed contract work-out program for U.S. Navy warship valve repair project.

H-R International Inc., Senior Vice President 1983-1984 Senior vice president in charge of marketing/sales for this $300 million international engineering and construction company while assisting with business reorganization and turnaround. Revamped proposal department and line sales.

Procon International Inc., (Subs. Of UOP) VP Marketing/Sales 1970-1983 Vice President, marketing/sales for this $500 million high technology engineering and construction company specializing in petroleum refining and other process industries. Responsible for worldwide sales, joint ventures, consulting services and project formation. Five years of strategic planning, financial analysis and new market development. Upgraded and realigned line sales yielding record sales and profits in a depressed market place. Obtained $1+ billion in sales, cost savings of $20 million, 400% proposal improvement and $15 million contract claim.

Education MBA Northern Illinois University; BA Chemistry St. Mary’s University

Engineering and Development

The Russell Energy Corporation has discussed the Engine/Generator design with FEV, an internationally recognized and highly respected powertrain and vehicle engineering company.

In those conversations, FEV indicated that they believe the design integration of the engine and generator provides some very interesting synergies and merits further studies. The Russell Energy Corporation intends to work with FEV to further develop the Engine/Generator design, taking it from a concept into a production program.

Manufacturing

The Russell Energy Corporation is interested in establishing Strategic Alliances and/or Licensing Agreements with Companies that are experienced in manufacturing and quality control. Companies must be fully committed to quality workmanship and on-time delivery. Although foreign investment will be considered all manufacturing must be done in the USA using only US citizens.

Manufacturing will include suppliers of the following goods or services;

- Raw Materials

- Castings

- Finished Machined Parts

- Electrical Coil Windings

- Electrical Control Equipment

- Fabricated Parts & Unit Enclosures

- Quality Assurance (parts), Unit Assembly, Unit Testing & Quality Assurance (finished product)

The Russell Energy Corporation will provide preferred status to early Strategic Alliances and/or Licensees.

Marketing and Distribution

The Russell Energy Corporation is interested in establishing Strategic Alliances and/or Licensing Agreements with Companies that are experienced in the marketing and distribution of "Power Generation Products". Companies must be fully committed to exceptional customer service and on-time delivery. The Russell Energy Corporation is committed to the development and sales of Eng/Gen units in a variety of sizes and applications worldwide. Opportunities are available for numerous qualified vendors.

The Russell Energy Corporation will provide preferred status to early Strategic Alliances and/or Licensees.

Installation and Servicing

The Russell Energy Corporation is interested in establishing Strategic Alliances and/or Licensing Agreements with Companies that are experienced in all the skills required for the installation and servicing of Eng/Gen units. Interested companies must be fully committed to exceptional customer service and the 24/7 delivery of services. Opportunities will be available for numerous qualified vendors worldwide.

The Russell Energy Corporation will provide preferred status to early Strategic Alliances and/or Licensees.

Energy Service and Sales

The Russell Energy Corporation is interested in establishing Strategic Alliances and/or Licensing Agreements with Companies that are interested in providing stationary or portable electrical energy distribution networks to be used in emergency or continuous duty applications. These opportunities will be of particular value for continuous duty electrical energy providers in remote locations, or in disaster relief applications worldwide.

The Russell Energy Corporation will provide preferred status to early Strategic Alliances and/or Licensees.

Investment Opportunity

The Russell Energy Corporation is interested in establishing Strategic Alliances and/or Licensing Agreements with Companies that are interested in providing funds for Russell Energy Corporation's development, testing and commercialization of the Eng/Gen technology.

The Russell Energy Corporation will provide preferred status to early Strategic Alliances and/or Licensees.

Business Overview

Our principal goal is to transform our patent portfolio into a product development and licensing business which results in significant job creation in the U.S.

We are focused on using a strategic alliance model to commercialize the patented Russell Engine/Generator technology.

The cornerstone of our business strategy is to align ourselves with experts and innovators in design, materials, development, testing, manufacturing, marketing, servicing and the distribution of Engine/Generator units and all related ancillary support products.

Cost and Efficiency of Micropower Generators

| Technology | Range (kW) | Installed Cost($/kW) | Efficiency |

|---|---|---|---|

| Engines | 30 to 1MW | 600-770 | 31-38% |

| Microturbines | 30 to 750kW | 700-800 | 20-32% |

| Fuel Cells | 30 to 750kW | 1500-3310 | 40-42% |

| Eng/Gen | 15 to 1MW | 200-300 | To be determined |

Potential Early Market Niches

On site use of available or harvested fuel by the Eng/Gen can efficiently produce electrical power with reduced cost and emissions.

| Niche | Leveraged Advantage |

|---|---|

| Waste Water Treatment | A minimal cost fuel, methane is produced in the treatment process. Specialized engines now used are high cost. |

| Pipeline Compressors | A low cost fuel, natural gas is carried in the pipeline. |

| Special Industry | Refinery, petrochemical and chlor alkali sites produce available fuel, hydrogen as a byproduct of processing. |

| Landfill Gas | Methane, a minimal cost fuel, is a byproduct of landfills. |

Market Segments

The high efficiency of the Eng/Gen power plant and low capital cost, provides economic advantages compared to competeting technologies.

| Market Segment | Capacity | Competing Technology | Allowable U.S. Prices ($/kW) |

|---|---|---|---|

| Commercial | 100kW-2MW | Purchased PowerReciprocating EngineGas TurbineMicroturbineFuel Cells | $1000-$2500 |

| Light Industrial | 100kW-5MW | Purchased PowerReciprocating EngineGas TurbineMicroturbineFuel Cells | $900-$2000 |

| Heavy Industrial | 5MW-200MW | Gas TurbineSteam TurbinePurchased Power | $700-$1300 |

| Distributed Power | 100kW-20MW | Gas Turbine/Combined CycleRecuperated Gas TurbineReciprocating EngineSolarWindFuel Cells | $800-$2500 |

The Eng/Gen can be designed for load factors of 80-95%. Allowable prices include total installed costs. Higher values reflect high value markets with limited market potential. Lower values represent the broadest market opportunity.

Business Opportunity Overview

Business opportunities offered to strategic alliances with REC will change with the evolution of the Eng/Gen technology and with future market growth. This will require new or existing strategic alliances to bring their unique skills and most efficient processes for improved quality and production to satisfy global demand from the USA.

This section will periodically provide new opportunities based upon the most current development status and requirements of the Eng/Gen technology.

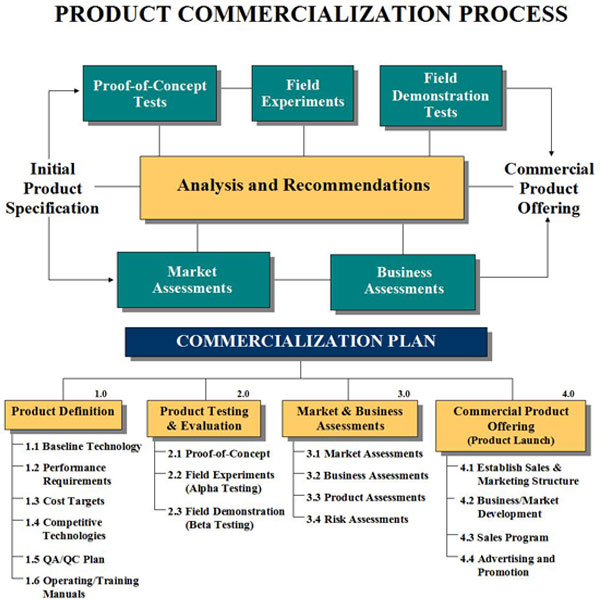

Business Roadmap

REC's business strategy involves developing Strategic Alliances, Joint Ventures and other lasting relationships to secure the components and competencies required to successfully commercialize the Eng/Gen technology in all its varied sizes and applications.

REC's also plans to commercialize world class power generation systems that will utilize the Eng/Gen technology. Systems will be designed to meet individual customer requirements and applications whether large or small. Examples would include systems designed for stores, hospitals, industrial applications, ships at sea or utility companies that support the power grid.

In all cases REC will demand the highest quality of design, engineering, materials, manufacturing excellence, quality control, parts interchangeability and compatibility. Provisions for system expandability and functionality will be tailored to the end-users requirements.

Constant attention to price, dependability and durability will be the norm with a distribution and service network tailored to the customers' needs and service requirements. From design through to start-up, warranty issues or maintenance REC will be there.